Safety footwear regulations

We provide you with a compilation of current Spanish regulations applicable to safety footwear.

The standards that are applicable to professional footwear are:

| OLD REGULATION | CURRENT REGULATION |

| EEN ISO 20345:2011 (in force until 11/11/2024) | EN ISO 20345:2022 |

| EN ISO 20346:2014 (pending publication in the Official Journal of the European Union) | EN ISO 20346:2022 |

| EN ISO 20347:2012 (pending publication in the Official Journal of the European Union) | EN ISO 20347:2022 |

These standards specify the basic and optional requirements for general-purpose professional footwear. They include mechanical risks, slip resistance, thermal risks, and ergonomic behavior.

To apply them, we use the methods and tests described in these other four standards:

- UNE-EN ISO 17075-1:2017 & UNE ISO 17075-2:2017: Leather. Chemical tests. Content of CR VI.

- UNE-EN ISO 20344:2022: Personal protective equipment. Test methods for footwear.

- UNE-EN 22568:2019: Foot and leg protectors. Requirements and test methods for puncture-resistant toecaps and insoles.

- UNE-EN 50321-1:2018 / AC:2018-00: Live working. Electrical protective footwear. Part 1: Insulating footwear and overshoe.

Special risks included in other complementary standards:

- UNE-EN ISO 17249:2013: Chainsaw protective footwear.

- UNE-EN 13832-2:2018y UNE-EN 13832-3:2018: Chemical protective footwear.

- UNE-EN 15090:2012: Firefighter footwear.

- UNE-EN ISO 2034-1:2017/A1:2020: Foundry and welding protective footwear. Part 1: Requirements and test methods for protection against foundry risks.

- EN ISO 20349-2:2017/A1:2020: Foundry and welding protective footwear. Part 2: Requirements and test methods for protection against welding processes.

- UNE-EN 13634:2017: Motorcyclist footwear.

| OLD REGULATION | |||

| Standards | Classes | Fundamental requirements | Additional requirements |

| EN ISO 20345:2011 SAFETY FOOTWEAR TOE CAP 200 JOULES AND COMPRESSION 15KN | Class I | SB |

|

| Class II | SB |

|

|

| EN ISO 20346:2014 PROTECTIVE FOOTWEAR TOE CAP 100 JOULES AND COMPRESSION 10KN | Class I | SB |

|

| Class II | SB |

|

|

| EN ISO 20347:2012 WORK FOOTWEAR | Class I | SB |

|

| Class II | SB |

|

|

SOLE SLIP RESISTANCE |

|

| Index | Clases |

| SRA |

Test floor: ceramic / lubricant: water with detergent ≥ 0.32 Flat ≥ 0.28 Heel (7° inclined footwear) |

| SRB |

Test floor: stainless steel / lubricant: glycerine ≥ 0.18 Flat ≥ 0.13 Heel (7° inclined footwear) |

| SRC |

Test floor: ceramic / lubricant: water with detergent Both conditions mentioned were required for SRA + SRB |

| ADDITIONAL REQUIREMENTS |

|

| Index | Classes |

| P |

Puncture resistance not less than 1100N |

| C |

Footwear with electrical resistance not exceeding 100 KΩ. |

| A |

Antistatic footwear. |

| E |

Electrically insulating footwear. |

| I |

Electrically insulating footwear. |

| WR | Water-resistant footwear. |

| WRU | Resistance to water absorption and penetration. |

| AN | Ankle protection |

| M | Metatarsal protection. |

| CR | Cut resistance. |

| HRO | Heat-resistant sole by contact. |

| HI | Insulating sole against floor heat. |

| CI | Insulating sole against floor cold. |

| FO | Resistance to hydrocarbons. |

| CURRENT REGULATION | |||

| STANDARD | CLASSES | FUNDAMENTAL REQUIREMENTS | ADDITIONAL REQUIREMENTS |

| EN ISO 20345:2022 Calzado de seguridad Puntera 200 Julios y compresión 15KN + deslizamiento cerámica con jabón. |

Class I | SB | S1 = SB + A + E + closed heel S2 = S1 + WPA S3 = S2 + P + sole with cleats S3L = S2 + PL + sole with cleats S3S = S2 + PS + sole with cleats S6= S2 + WR S7= S3 + WR S7L= S3L + WR S7S= S3S + WR |

| Class II | SB | S4 = SB + A + E + closed heel S5 = S4 + P + sole with cleats S5L = S4 + PL + sole with cleats S5S = S4 + PS + sole with cleats |

|

| EN ISO 20346:2022 Calzado de protección Puntera 100 Julios y compresión 10KN + deslizamiento cerámica con jabón. |

Class I | PB | P1 = PB + A + E + closed heel P2 = S1 + WPA P3 = P2 + P + sole with cleats P3L = P2 + PL + sole with cleats P3S = P2 + PS +sole with cleats P6= P2 + WR P7= P3 + WR P7L= P3L + WR P7S= P3S + WR |

| Class II | PB | P4 = PB + A + E + closed heel P5 = P4 + P + sole with cleats P5L = P4 + PL + sole with cleats P5S = P4 + PS + sole with cleats |

|

| EN ISO 20347:2022 Calzado de trabajo Deslizamiento cerámica con jabón. |

Class I | OB | O1 = OB + A + E + closed heel O2 = S1 + WPA O3 = O2 + P +sole with cleats O 3L = O2 + PL + sole with cleats O3S = O2 + PS + sole with cleats O6= O2 + WR O7= O3 + WR O7= O3L + WR O7= O3S + WR |

| Class II | OB | O4 = OB + A + E + closed heel O5 = O4 + P + sole with cleats O5L = O4 + PL + sole with cleats O5S = O4 + PS +sole with cleats |

|

| ADDITIONAL REQUIREMENTS FOR PROFESSIONAL FOOTWEAR | |||

| SOLE SLIP RESISTANCE | |||

| SR | Test floor: ceramic tile / lubricant: glycerin ≥ 0.19 Forward heel slip. ≥ 0.22 Backward front part slip | ||

|

OTHER ADDITIONAL REQUIREMENTS |

|||

|

P |

Puncture resistance not less than 1100N. Metal insole. 4.5mm punch. | ||

|

PL |

Puncture resistance not less than 1100N. Non-metal insole. 4.5mm punch. | ||

| PS | Puncture resistance not less than 1100N. Non-metal insole. 3mm punch. | ||

| C | Footwear with electrical resistance not exceeding 100 KΩ | ||

| A | Antistatic footwear. | ||

| E | Energy absorption in the heel not less than 20 J. | ||

| I | Electrically insulating footwear. | ||

| WR | Water-resistant footwear | ||

| WPA | Resistance to water absorption and penetration | ||

| AN | Ankle protection. | ||

| M | Metatarsal protection. | ||

| CR | Cut resistance | ||

| HRO | Heat-resistant sole by contact. | ||

| HI | Insulating sole against floor heat. | ||

| CI | Insulating sole against floor cold. | ||

| FO | Resistance to hydrocarbons | ||

| SC | Protection against toe abrasion | ||

| LG | Grip on stairs | ||

FOOTWEAR CLASSIFICATION BASED ON MATERIAL TYPE

| Footwear Type | Protection Level Regulation |

| Class I |

Footwear made of leather and other materials, excluding all-rubber and all-polymeric footwear. |

| Class II |

All-rubber (vulcanized) or all-polymeric (injected or molded) footwear. |

CLASSIFICATION BASED ON LEVEL OF PROTECTION

Protection Level Regulation

| Footwear Type | Protection Level Regulation | Standards |

| Safety Footwear |

Footwear equipped with a toe cap resistant to an impact of 200J and a compression of 15 KN. |

EN ISO 20345:2011 |

| Protection Footwear |

Footwear equipped with a toe cap resistant to an impact of 200J and a compression of 15 KN, in addition to slip resistance on ceramic tile flooring with soap. |

EN ISO 20345:2022 |

| Protection Footwear |

Footwear equipped with a toe cap resistant to an impact of 100J and a compression of 10 KN. |

NEN ISO 20346:2014 |

| Protection Footwear |

Footwear equipped with a toe cap resistant to an impact of 100J and a compression of 10 KN, in addition to slip resistance on ceramic tile flooring with soap. |

EN ISO 20346:2022: |

| Work Footwear |

Footwear that does not guarantee protection against impact or compression in the front part of the foot, even if it incorporates other safety elements. |

EN ISO 20347:2012 |

| Work Footwear |

Footwear that does not guarantee protection against impact or compression in the front part of the foot, even if it incorporates other safety elements, and also has slip resistance on ceramic tile flooring with soap.n. |

EN ISO 20347:2022 |

Based on Height:

| Footwear Type | Classification | Height |

| Shoe |

A |

< 12,1 cm |

| low boot |

B |

> =12,1 cm |

| mid-calf boot |

C |

> =19,2 cm |

| long boot |

D |

>= 30,0 cm |

| extra-long boot |

E |

> 30,0 cm (Boot D + extension) |

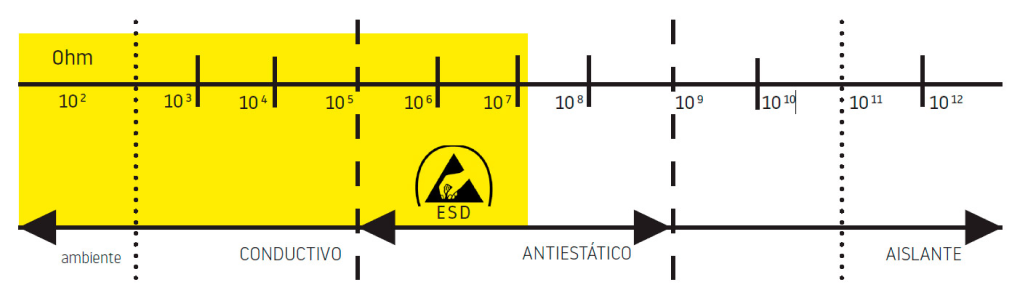

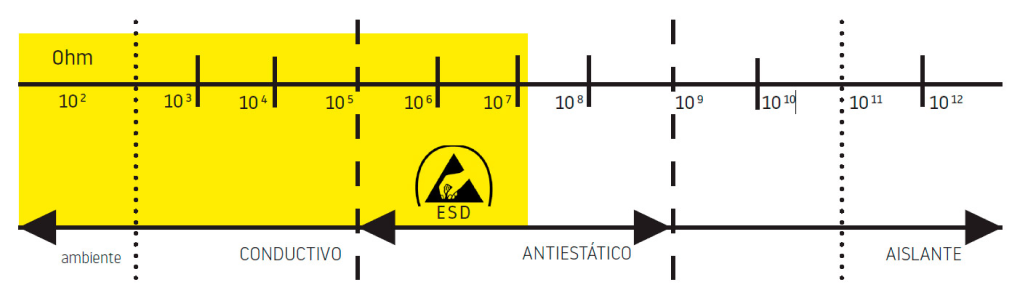

Based on Electrical Resistance:

In terms of their resistance to the passage of electrical current, we have:

| Footwear Type | Protection Level Regulation |

| Conductive Footwear |

They have an electrical resistance lower than 105 Ohms. Completely eliminates electrostatic charges. It does not offer any protection to the operator against the passage of current, so it is used in very specific jobs, such as those with potentially explosive atmospheres, whether they involve flammable vapors or suspended flammable dust. |

| Antistatic Footwear |

They have an electrical resistance between 105 Ohms and 109 Ohms. It is the most commonly used in most jobs, as it is very versatile, offering some "protection" to the user against the passage of current (although it cannot guarantee adequate protection against large electrical discharges) and allows for the dissipation of most electrical charges. |

| ESD Footwear |

According to EN 61340-5-1:2016 regulations, the ground resistance must be equal to or less than 108 Ohms. It is a special case within the range of lower Antistatic footwear. It dissipates almost all electrical charges, offering very minimal protection against the passage of electrical current, but sufficient for the protection of electronic components or integrated circuits within special rooms called EPA, where the entire room is grounded. |

| Insulating Footwear |

They have an electrical resistance greater than 109 Ohms. It provides complete protection to the user against electrical shocks, preventing the dangerous passage of current through the body. |