Safety gloves features

Confección

LEATHER

It is the oldest material used in the manufacture of gloves, a natural, breathable and flexible product, which covers much of the common risks of most industries.

It comes in two forms: garin and suede.

Full grain

It is the best part of leather (outside of the dermis). It provides touch, flexibility and high mechanical resistance.

Suede

Inner layer, considered as a by-product thereof. It is generally harder and heavier than leather. It has good resistance to cutting, drilling and heat (depending on thickness) and aids grip on wet or damp objects.

We can distinguish suede between:

· Top suede: Used for cheaper and less strong and durable gloves.

· Flesh split: Used for split or reinforced gloves and welding items. The thickness of the split will determine the duration of the glove.

Kidskin (goat)

Its limited thickness requires the exclusive use of the variety grain, which provides the best mechanical performance since the fibres are not cut. It is a flexible and highly resistant skin with an excellent finish.

Lamb

With similar characteristics to goatskin, it is less resistant to abrasion. Very soft, this type of skin thickness provides the best thickness to dexterity ratio.

Cowhide

It offers excellent mechanical properties and is highly resistant to perforation. Breathable and comfortable, it is characterized by its durability and excellent abrasion resistance.

Buffalo

Its properties are similar to those of cowhide, presenting the disadvantage that it eventually hardens and loses flexibility.

Deer

Similar to cowhide’s properties, it is very flexible, soft and resistant to abrasion, cutting, tearing and perforation.

Pigskin

It allows higher ventilation than other skins, although its resistance to abrasion, cut and tear is more limited, and offers less comfort, flexibility and dexterity.

Synthetic leathe

Technological developments have allowed the production of materials such as Clarino, a synthetic leather that is an alternative to natural skin for making protective gloves against mechanical risks. It is a washable material and has excellent resistance to abrasion with uniform quality and comfortt.

Shoulder

It is the most economical part, providing long and thinner fibres than the belly.

Back

Midsection, it is the choicest part.

Belly

It is a less resistant part than the back and the fibres thicknesses are patchy.

WaterproofTo improve its characteristics and the level of benefits, the leather may undergo various treatments, such as:

Waterproof

Using mineral or synthetic oils, resins or oils to increase the leathers resistance to water and mechanical abrasion, comfort, dexterity and durability characteristics

Oil- resistant

It is a treatment with mineral, synthetic oils or fluorinated resins which improve the leather’s resistance to water and oils. This treatment optimizes the leather’s mechanical performance: abrasion resistance, increased comfort (flexibility), greater range of motion (touch) and duration.

Fire- resistant

Improves the resistance of the skin against contact with heat: maintaining flexibility and reduces shrinkage.

There are many combinations of materials (fabric and coating material) and are determined by the desired properties to the glove. For example, we can highlight:

Cotton / polyester

Cotton / polyester with latex coating for general work.

Woven nylon

Woven nylon with polyurethane coating for delicate work.

Kevlar

Kevlar with PVC coating for cut resistance.

Cotton / Polyester

Cotton / Polyester with nitrile coating for resistance to oils and chemicals.

Cotton / polyester

Cotton / polyester with PVC coating for protection against the cold.

Woven nylon / Thunderon

Woven nylon / Thunderon with PU coating to dissipate static electricity.

Safety

GLOVE PARTS

The main parts of a leather glove are the palm, the back of the hand, thumb, fingers, cuff and sleeve.

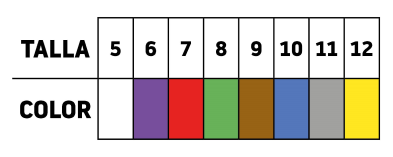

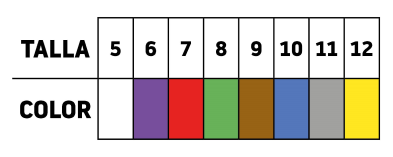

Gloves are made of woven fabric (or mesh fabric formed by interlocking loops of yarn), the needle is the main element of the work. The gauge is the number of needles of a loom in an English inch (2.54 cm).

The finer is the gauge, the thicker the glove, and the greater the protection provided. The thicker the gauge, the finer the glove, achieving greater dexterity and sensitivity, but a lower level of protection. Thus, gauge 7 employs a thick thread; gauge 10, a médium thread; and gauge 13, a thin thread.

La palma del guante puede presentar un acabado liso (facilita el lavado y dificulta la fijación de la suciedad). El acabado rugoso, con diferentes niveles de rugosidad, mejora la prensión de objetos abrasivos y resbaladizos. Algunos guantes poseen relieve en la palma y en los dedos (picos), lo que optimiza la capacidad de prensión.

Cuando no es precisa la estanqueidad, el dorso del guante puede ser aireado para ventilación de la mano y mayor confort del usuario.

As for the cuffs or sleeves, we can find different types of finishes:

Straight fit

The standard finish. It is used in unsupported gloves.

Zigzag or serrated cut

Increases the life of the gloves with textile backing.

Rolled edge

In the case of thin gloves, improves resistance to tearing when putting on the glove.

Safety sleeve

Enables greater wrist protection, is easy to take off quickly and allows ventilation of the hand.

Split sleeve

As above, ensures protection of the forearm and the lining of the sleeve.

Ribbing

Improves tear resistance.

Sealing sleeve

Protects the arm from injury.

Elastic cuff

It has a good fit and grip on hand. Generally made of knitted fabric, prevents the entry of foreign bodies in the area of the wrist and provides protection from the cold.

There are various special treatments inside of the glove:

Chlorinated

This procedure involves washing the glove with chlorinated water, where traces of metals, organic matter, bacteria and viruses are removed. This treatment gives the glove a velvety touch, making it easier to put on and take off.

Powdered

A powder is applied inside the glove, generally corn starch (or other hypoallergenic substances), which limits the effects of perspiration and making it easier to put on and take off.

Flocking

The glove is lined with a cotton fibre making it soft and pleasant to the touch. Furthermore, flocking provides sweat absorption.

Endurance

TEXTILE / SYNTHETIC FIBERS

In addition to fur, textile fibers and other synthetic products are also used.

Cotton

A natural and highly absorbent fibre, which allows ventilation and prevents irritation. It presents good mechanical strength and an average thermal quality. It is comfortable despite prolonged use.

Polyamide (Nylon)

It is abrasion resistant, but does not absorb moisture. It can be made with high toughness, improving its mechanical performance. Abrasion resistant, doesn’t deform and dries quickly.

Polyester

A synthetic fibre developed by DuPont in 1951. It doesn’t allow ventilation, so it is often combined with natural fibres such as cotton. It offers great abrasion resistance, it is soft and warm, and a good insulator.

Kevlar®

A para-aramid synthetic fibre which is five times stronger than steel wire, fire retardant and cut resistant. Carbonized between 425 and 475 ° C. It doesn’t melt, is self-extinguishing, has high dimensional and chemical stability and it is very soft.

Nomex®

A polymer aramid fibre that does not burn. When near a flame, the fibres create a thick barrier of air between the heat source and the skin.

HDPE

High density polyethylene, at equal weight, is ten times stronger than steel. With excellent anti-cutting properties, it is resistant to many chemicals and ultraviolet radiation resistant products.

Thunderon®

An organic fibre which discharges static electricity by electrostatic induction, which prevents spoilage or tampered componentss.

Spectra®

A high density polymer which is very resistant to cutting. At equal weight, this fibre is ten times stronger than steel and 40% stronger than aramid fibres.

Thinsulate®

A fine nonwoven polyester fibre. Excellent cold insulation, comfort and moisture resistant.

Natural latex

Natural rubber (Hevea brasiliensis) with high comfort, flexibility and dexterity level. Aqueous chemical resistant products, but it degrades with hydrocarbons. It can cause allergies.

Polychloroprene (neoprene)

Synthetic rubber with high flexibility, ductility and resistance to gasoline, oil and lubricants. Avoid latex allergies. Good resistance to ozone.

Nitrile (Nitrile Butadiene Rubber)

Synthetic rubber with good resistance to oils, lubricants and petroleum products. Good mechanical strength. Resistant to a temperature of 0 to 104 ° C.

Polyurethane

Synthetic material with excellent elasticity, and resistance to abrasion and tension.

Pvc

Synthetic polymer provides good resistance to aqueous chemicals (acids and alkalis) and fats and hydrocarbons. Has good flexibility and abrasion resistance. It causes no allergies.

Butyl

High-tech synthetic rubber, resistant to organic and corrosive chemicals. It provides high impermeability to gases and steam, maintaining flexibility even at low temperatures.

Viton

Fluoropolymer which is the most resistant of all synthetic rubbers. Protects against toxic and highly permeable chemicals. It is an excellent resistant to most known solvents, gas and steam. It is flexible and offers good resistance to abrasion and cutting.